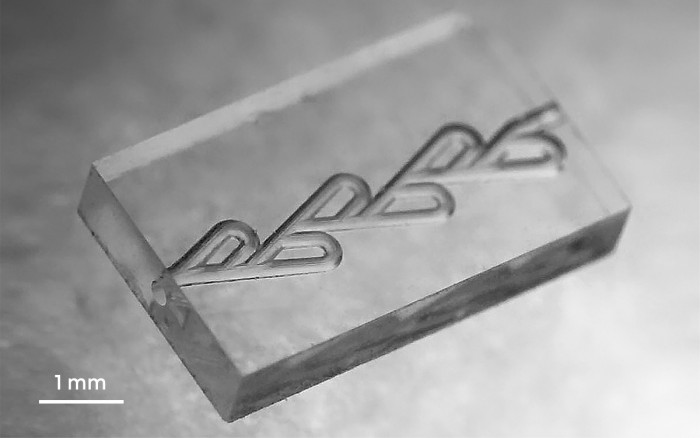

Tesla Valve

One of the most promising applications for SLE is microfluidics. SLE-made surfaces can have relatively low surface roughness (~200 nm RMS). SLE technology far exceeds ablation in terms of flexibility and enables the production of 3D free-form structures, such as channels with integrated functional elements, or 3D channel systems embedded inside the volume of glass, bringing new capabilities and flexibility to the field. These properties make it possible to avoid other supplementary processes such as sealing ablated channels or the need to use other manufacturing techniques for integrating some more trivial structures. In this way, Tesla valve microfluidic channels can be fabricated inside the volume of glass. This microchannel design allows the liquid to flow in only one direction.