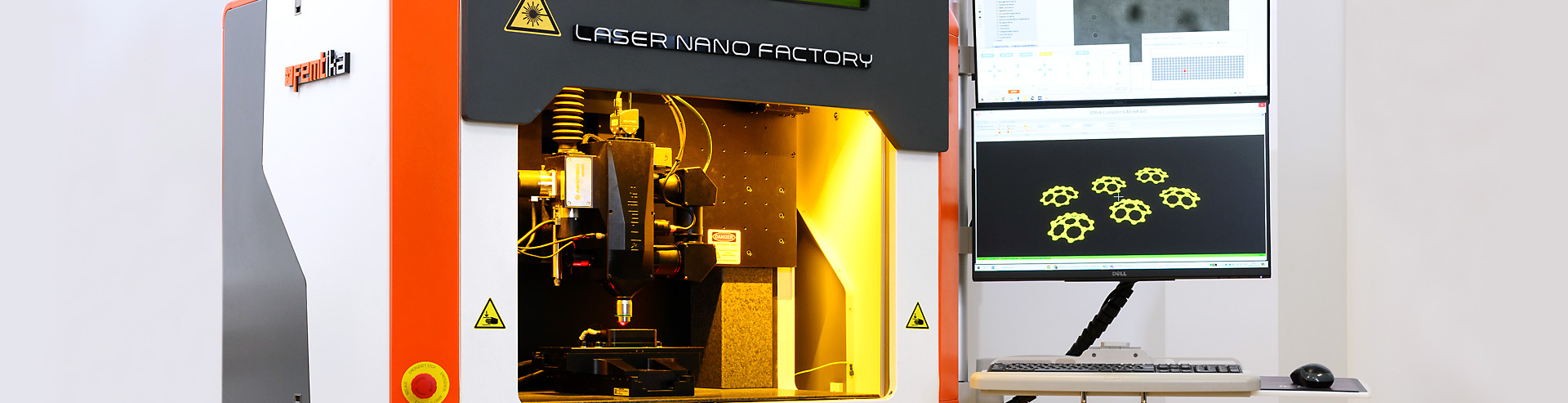

Laser Nanofactory Hybrid Fabrication

FEATURES

- Additive and subtractive techniques combined in one Laser Nanofactory system

- Arbitrary-shaped 3D structures from micrometers to centimeters scale

- Fast switch from additive to subtractive microfabrication

- Customizable configuration – integrate additional devices

Femtosecond lasers are extremely versatile tools allowing a great variety of different microfabrication processes. Each process has its own requirements for laser, beam delivery or material parameters. Our Laser Nanofactory workstation allows hybrid fabrication, meaning that various processes are supported by the same equipment. The two of our most frequently used processes are multiphoton polymerization and selective glass etching, however that is far from all! By precisely tuning its parameters the same machine is capable to perform more processes including:

- Refractive index modification of transparent materials

- Micro-ablation

- Surface structuring

- Micro-welding

In addition, Laser Nanofactory is a modular system, allowing further adaptation to your application. It supports various sample holders (e.g. for microscope slides, wafers, fibers) and different fabrication heads, optimized for your desired laser applications.