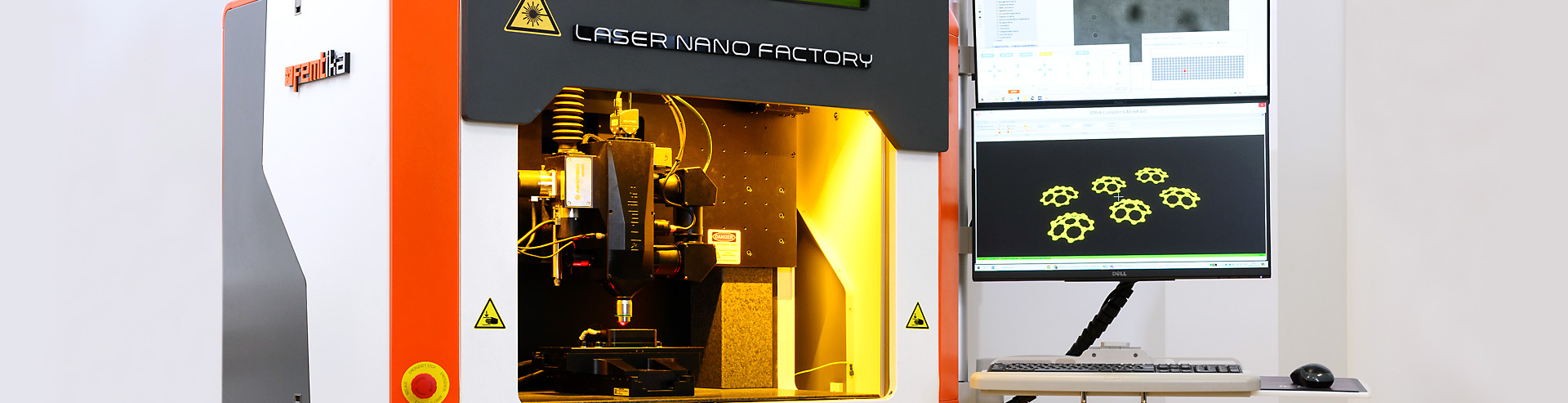

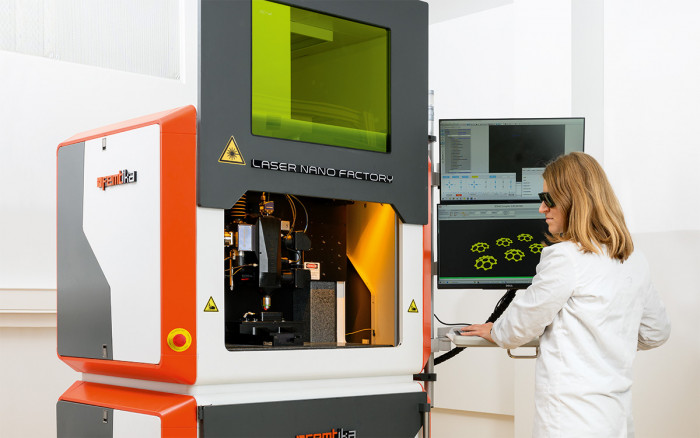

Laser Nanofactory Multi-Photon Polimerization

FEATURES

- Nanometer resolution additive manufacturing technique

- True 3D structures in micrometer scale

- Various polymers available

- Stitching error-free manufacturing

Multiphoton-polymerization (MPP) is a technology that enables the production of arbitrary shape polymeric structures within submicrometric resolution. First, a photoresist sample is prepared by drop-casting polymer material mixed with a photoinitiator on the glass slide and then pre-baking. Afterward, the 3D microstructure is fabricated using a direct laser writing technique. Consequently, the polymer hardens in places of drop where it is affected by laser radiation due to a process called photopolymerization. Finally, the microstructure is immersed in an organic solvent to develop an unpolymerized photoresist.

MPP has become a popular choice in the manufacturing of microelectronic devices due to its exceptional ability to produce intricate and precise structures. Its highly focused light source also enables the creation of complex 3D shapes with ease.

Applications

- Micro-optics

- Micro-mechanics

- Scaffolds

- Sensors

- Interconnects