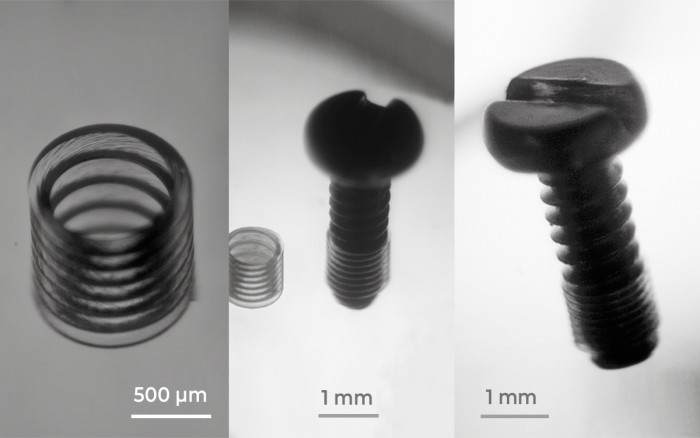

Selective laser etching (SLE) is a femtosecond laser-based technology that enables 3D printing of complex glass microparts in two technological steps: direct laser writing inside the volume of glass and subsequent etching. The SLE technology permits straightforward conversion of the desired CAD design to a 3D micropart. Even mm-size structures with a few micrometers of precision can be printed in this way. One example is threads for screws in glass. Sub-mm size thread structure is hard to fabricate in glass due to its spiral shape and the need for high precision and low surface roughness.